The Industrial Internet of Things (IIoT) is revolutionizing how industries operate by connecting machines, devices, and sensors to gather and analyze real-time data from the physical world. This convergence of information technology (IT) and operational technology (OT) underpins the broader Industry 4.0 movement – enabling smarter factories, intelligent infrastructure, and data-driven decision making in sectors from manufacturing to energy. Crucially, IIoT initiatives are no longer experimental; over 90% of organizations adopting IoT use cases now report positive returns on investment. In other words, modern industrial IoT deployments are delivering tangible value, dispelling earlier concerns about “pilot purgatory” where projects failed to move beyond proof-of-concept. For OT teams and CTOs, the message is clear: embracing IIoT can unlock new levels of efficiency, safety, and innovation – provided it’s implemented with a strategic, scalable approach.

Yet, launching IIoT in an industrial environment is not as simple as adding a few sensors. Unlike consumer IoT, industrial deployments must contend with legacy equipment, strict reliability and security requirements, and coordination across multiple teams. OT leaders often find themselves bridging a cultural and technical gap between plant-floor operations and enterprise IT. Data that has been siloed in separate control systems for decades now needs to be integrated and shared for analytics. Despite these challenges (which we’ll explore later), the payoff is compelling. Companies that successfully implement IIoT are seeing streamlined operations, lower downtime, and improved visibility across their assets. They are able to predict problems before they happen, respond faster to changing conditions, and make decisions based on real-time insights rather than guesswork. In the following sections, we provide an expert overview of how industrial IoT is transforming key sectors, the benefits it delivers, and best practices to overcome common hurdles. This guide is for OT professionals and CTOs seeking to understand the what, why, and how of IIoT in today’s industrial and infrastructure environments.

Why Industrial IoT Matters

Industrial IoT isn’t just a tech buzzword – it directly addresses longstanding operational challenges that organizations across sectors have struggled to overcome. Whether it’s outdated infrastructure, reactive maintenance practices, or siloed operations, IIoT enables a shift toward proactive, data-informed decision-making. By instrumenting physical assets and processes with connected sensors, IIoT enables organizations to monitor conditions continuously, analyze performance trends, and automate responses at scale.

From reducing unplanned downtime in factories to ensuring environmental compliance in healthcare and enabling real-time fleet monitoring in logistics, the applications are as diverse as the industries themselves. Below is a streamlined overview of how IIoT is shaping critical sectors.

Enhanced Efficiency & Productivity

IIoT provides unprecedented visibility into operations, allowing companies to streamline processes and eliminate inefficiencies. Connected sensors collect data on machine performance, energy use, output rates and more, enabling real-time optimization. For example, in manufacturing, IoT-driven monitoring identifies bottlenecks on production lines and suggests adjustments on the fly. Armed with live data, teams can implement process automation and other improvements that boost labor productivity and throughput (per IoT Analytics major IoT rollouts have improved labor efficiency by ~8% on average). Furthermore, real-time telemetry enables predictive maintenance, so maintenance is performed exactly when needed – minimizing unplanned downtime and keeping equipment running at peak efficiency.

Cost Savings & ROI

The efficiencies gained from IIoT translate into significant cost reductions and fast ROI. Proactive maintenance alone can lower maintenance costs and prevent expensive breakdowns. One analysis found that over half of companies implementing IoT-based quality control or automation achieved payback in under 2 years. Energy management is another area of savings: IoT sensors and smart controls optimize energy consumption in real time, cutting utility bills by turning off or dialing down systems when not needed. For example, commercial buildings using IoT for smart HVAC and lighting have significantly reduced energy waste. Supply chain visibility through IoT prevents losses and reduces inventory costs by ensuring the right materials are in the right place at the right time. All these optimizations add up – studies confirm that organizations see positive financial returns in the vast majority of industrial IoT projects.

Increased Safety & Risk Mitigation

In high-risk industrial settings, IoT technologies serve as an extra set of eyes and ears to protect workers and assets. Sensors can continuously monitor environmental conditions (temperature, air quality, radiation, etc.) and equipment health, issuing alerts for anomalies that could signal safety hazards. For instance, IoT wearables and fixed monitors on a construction site can detect excessive vibration or structural strain and warn personnel to evacuate before a collapse. In manufacturing plants, real-time machine data can flag abnormal temperatures or pressures, allowing operators to shut down equipment safely before a failure causes an accident. Automation also helps remove people from harm’s way – think of drones inspecting hazardous areas or autonomous robots handling dangerous tasks in mining and oil & gas. By predicting failures and automating emergency responses, IIoT helps companies reduce incidents, injuries, and unplanned outages while also maintaining compliance with safety regulations.

Higher Quality & Customer Satisfaction

oT-driven quality control ensures that products and services consistently meet standards, which is vital for competitiveness. By monitoring production parameters in real time and catching deviations immediately, IoT systems help eliminate defects and reduce waste. In industries like pharmaceuticals or food, IoT sensors track conditions like temperature and humidity throughout production and storage to guarantee quality and compliance. The payoff is not only fewer rejects but also richer data to improve processes – analytics can pinpoint root causes of quality issues and guide continuous improvement. Moreover, IIoT enables new connected services that enhance customer experience. Manufacturers can offer IoT-powered remote monitoring of their equipment at customer sites and deliver proactive maintenance or performance optimization. A classic example is industrial OEMs using IoT to monitor their machines (turbines, engines, etc.) in the field and alert customers of issues before failure. This kind of value-added service, made possible by IoT data, deepens customer relationships and can even unlock new revenue streams.

In short, industrial IoT helps organizations “do more with less” – less downtime, less waste, less risk – while delivering more output, insight, and value for the business. These benefits apply across a wide array of sectors and use cases, which we explore next.

Industrial IoT Applications Across Key Sectors

Industrial IoT’s versatility means it can be applied to virtually every domain where physical operations take place. Below, we highlight how IIoT is transforming several major sectors, from commercial real estate to heavy industry. While each sector has unique drivers, they all share common IoT themes: deploying sensors and connectivity to gain visibility, using analytics/AI to derive actionable insights, and integrating with existing systems to automate and streamline workflows.

Commercial Buildings & Real Estate

In commercial real estate and facility management, IoT is the cornerstone of the “smart building.” Property owners are using IoT sensors and connected devices to optimize how buildings are operated, maintained, and experienced by occupants. A prime example is building environmental monitoring: sensors track temperature, humidity, CO₂ levels, light, noise and other conditions throughout a facility. An international real estate firm, JLL (a Fortune 500 company), outfitted dozens of office buildings with IoT devices measuring these factors, feeding data into a central platform. The insights allowed JLL to understand actual space usage patterns and adjust heating, cooling, and lighting for comfort and efficiency, as well as schedule predictive maintenance on HVAC and other equipment at optimal times. This type of IoT-driven facilities analytics reportedly cut energy consumption and improved tenant comfort simultaneously.

Beyond HVAC and energy management, occupancy and motion sensors are used for smart space management and security. They detect which areas are in use, enabling dynamic control of lighting/HVAC (to save power in unoccupied zones) and providing data on space utilization for planning. IoT-based access control systems can monitor entries/exits and even integrate with emergency response – for example, during a fire alarm, knowing via IoT which rooms are occupied helps first responders. Another key application is asset tracking and maintenance of building systems: IoT sensors on elevators, chillers, or generators continually report performance. This allows facility teams to fix small issues (like a vibration increase in a motor) before they escalate into major failures. In essence, IoT turns a passive building into an active, responsive environment – adjusting conditions automatically and flagging issues in real time. This not only reduces operating costs and downtime, but also makes properties more attractive to tenants with promises of better comfort, air quality, and safety monitoring. As Tektelic put it, “The bottom line is that the Internet of Things is changing the real estate landscape…”. Commercial building owners need to stay ahead of the curve or risk obsolescence.

Manufacturing & Industrial Operations

Manufacturing was one of the earliest adopters of IIoT, often under the banner of Industrial Automation or Industry 4.0. In factories, IoT connects the various stages of production – machines, conveyors, robots, quality control devices – to create a transparent, intelligent production line. One fundamental use is real-time condition monitoring of equipment on the factory floor. By equipping machines with sensors (measuring parameters like vibration, temperature, motor current, etc.), manufacturers gain continuous insight into how each asset is performing. This data is analyzed to detect inefficiencies (e.g. a machine running below capacity due to a hidden bottleneck) and identify maintenance needs. Indeed, predictive maintenance (PdM) has become a star application in manufacturing IIoT. Instead of relying on fixed maintenance schedules or waiting for a breakdown, companies use IoT sensor data and AI models to predict when a machine will require service. This proactive approach has major payoffs: downtime is minimized and equipment lifespan is extended. For instance, Colgate-Palmolive adopted an AI-enabled predictive maintenance solution using wireless sensors to monitor machine health 24/7, diagnosing issues early and minimizing downtime. For example, the system detected rising temperatures in the drive motor of a tube maker and alerted the plant team, enabling them to fix a cooling problem before failure. This intervention prevented approximately 192 hours of unplanned downtime and preserved the equivalent of about 2.8 million tubes of toothpaste, along with avoiding replacement and variable conversion costs. It’s easy to see the ROI when a single avoided outage can save millions of dollars.

Quality assurance is another area transformed by IIoT. In “smart factories,” connected sensors and cameras inspect products on the line in real time, and any deviation from specs triggers an immediate response (such as ejecting a defective item or adjusting machine settings). This IoT-driven quality control has proven effective – over half of manufacturers in one survey had adopted IoT-based quality management, with many seeing payback in under two years. Moreover, the data from these IoT systems can be fed into continuous improvement initiatives (Six Sigma, Lean, etc.), providing granular evidence of where processes could be improved. Beyond the factory walls, manufacturers use IIoT to manage inventory and supply chains through smart tracking of materials and products. IoT tags (e.g. RFID, GPS) on pallets or components allow just-in-time logistics and reduce misplaced inventory. In summary, IIoT in manufacturing creates a digitally connected production environment where machines can “talk” to systems and even to each other – enabling autonomous adjustments, minimizing downtime, improving quality, and ultimately increasing output. It’s not surprising that process automation is now the #1 most adopted IoT use case globally, as companies strive for the efficiency and agility that IIoT-powered operations provide.

Logistics & Warehousing

The logistics sector – including warehouses, distribution centers, and in-transit freight – has embraced IoT to gain end-to-end visibility of assets and goods. In large warehouses, one key application is asset tracking and fleet management inside the facility. By equipping forklifts, carts, containers, and inventory items with IoT trackers, companies can monitor the movement and location of everything in real time. A compelling example comes from Budweiser Budvar Brewery, that modernized its warehouse tracking using a real-time locating system (RTLS) based on ultra-wideband (UWB) technology. The brewery replaced its legacy RFID-based forklift tracking with UWB RTLS, which accroding to the supplier delivered ~99 % system uptime (compared with ~80 % uptime under the previous system) and provided continuous, precise visibility into the location and movement of forklifts and inventory. With real-time insights — including distance traveled, utilization metrics, and heatmaps — logistics managers improved warehouse utilization by about 19 %, effectively increasing throughput and operational efficiency without expanding physical space visibility.

IoT is also used for condition monitoring in logistics, especially for cold chain and sensitive goods. Smart IoT data loggers travel with perishable or high-value products to record temperature, humidity, shock, etc., and they can alert managers if conditions go out of range (for example, if a refrigerated truck’s temperature rises dangerously, or a package is opened when it shouldn’t be). This ensures product quality and security through the supply chain. Additionally, IoT-enabled fleet telematics (discussed more under Mobile Assets & Fleet below) benefit logistics by optimizing delivery routes and providing real-time ETA updates. In yards and ports, IoT solutions track containers and coordinate loading/unloading to reduce delays. Inventory management within warehouses is another big winner: RFID and vision-based IoT systems can automatically count stock levels and trigger re-orders or alerts to prevent stockouts. Ultimately, IoT in logistics and warehousing brings the power of real-time data to what used to be a very manual process – companies can operate leaner inventories, respond faster to disruptions, and increase the speed and accuracy of fulfilling orders.

Energy & Distributed Infrastructure

The energy and utilities sector spans power generation plants, electricity grids, oil and gas facilities, renewable farms, and more – all of which are being enhanced by IoT and remote monitoring. A major trend is the development of the smart grid, where IoT sensors and smart meters are deployed throughout the electricity distribution network to provide granular, real-time data on grid conditions. For example, EDF (Electricité de France), one of Europe’s largest utilities, uses IoT sensors and smart meters across its grid to improve performance and reliability. The real-time data allows better outage detection, asset health monitoring, and integration of renewable energy sources into the grid. With IoT-based monitoring, utilities can pinpoint a failing transformer or downed line immediately (rather than waiting for customer calls) and dispatch crews more effectively. It also helps in balancing supply and demand, especially as renewable generation (solar, wind) fluctuates – sensors feed data to AI systems that can adjust distribution or storage to maintain stability.

In the oil & gas industry, which often operates remote and hazardous infrastructure, IoT has become indispensable for remote asset management. Companies like Shell and BP are leveraging connected sensors on wells, pipelines, and refineries to monitor conditions without requiring personnel on-site 24/7. For instance, Shell uses IoT for remote well monitoring: downhole sensors and surface equipment send continuous data on pressure, flow rates, temperature, etc., enabling engineers to optimize production and detect issues (like a leak or equipment wear) early. BP is another example – it streams 250 billion data signals per month from its global operating assets into a centralized IoT hub, using a digital twin to monitor asset performance in real time and even to find ways of reducing emissions. These digital twins – virtual models of physical assets updated continuously via IoT data – allow energy companies to run simulations and predictive analytics (for example, forecasting when a sub-sea valve might fail or how to reroute power during peak loads). The result is higher uptime and safer operations; issues can be fixed proactively rather than reactively.

Energy firms are also adopting IoT at renewable generation sites: wind turbines and solar panels bristle with sensors and connectivity so that operators can remotely track output and equipment status across dispersed locations. IoT data helps coordinate these distributed resources and integrate them into the grid smoothly (ENGIE, for instance, built a platform using Azure IoT Edge to gather real-time data from wind, solar, hydro assets worldwide for performance optimization). Additionally, predictive maintenance is as valuable in energy as in manufacturing – predicting a failing turbine bearing or a corroding pipeline section can prevent catastrophic failures. In summary, IoT enables the energy sector to move from manual, periodic checks to continuous, automated oversight. The payoff is huge in terms of reliability (fewer blackouts, spills, or accidents) and efficiency (longer asset life, reduced maintenance costs, and optimized energy production).

Healthcare & Critical Facilities

In hospitals, clinics, and other critical facilities, IoT is improving operations and patient care through better monitoring of both equipment and environments. A key IIoT application in healthcare is remote equipment monitoring for critical medical devices. Machines like MRI scanners, ventilators, lab analyzers, and backup generators are outfitted with IoT sensors that continually report on their performance and status. This allows hospital maintenance teams to perform predictive maintenance – for example, replacing a part in an MRI machine at night before it fails during a busy day of patient scans. Ensuring high uptime for critical equipment is literally life-saving in healthcare. IoT monitoring prevents unexpected equipment failures that could disrupt patient care, thereby improving reliability and safety in the facility. Some hospitals have even tied IoT device data into their maintenance ticketing systems, so alerts from a failing device automatically create a service order.

Another important use is environmental monitoring for safety and compliance. Healthcare facilities must maintain strict conditions in certain areas – think of pharmaceutical storage refrigerators, surgical suites, or data centers in hospitals. IoT sensors track parameters like temperature, humidity, differential air pressure, and air quality in real time. If a vaccine storage fridge starts warming above safe temperature, the IoT system will send instant alerts so staff can take action (moving the vaccines or fixing the fridge) before the inventory is ruined. Similarly, IoT air quality sensors can ensure operating rooms meet air change and sterility standards, or that generators in a “critical facility” (like a 911 call center or a bank data center) have proper ventilation and fuel levels. Compliance with regulations (e.g. for storing medications or food in hospitals) is made much easier with automated IoT logging rather than manual checks.

Healthcare operations also benefit from asset tracking, similar to general industry but applied to hospital needs. Bluetooth or RFID tags on mobile medical equipment (wheelchairs, IV pumps, defibrillators) allow staff to quickly locate the nearest device when every second counts. During emergencies, knowing the real-time location of critical assets and even patients (via wristband trackers) can streamline response and workflow. Some hospitals use IoT to monitor patient flow and wait times – tracking how patients move from ER to imaging to bed, etc., to identify bottlenecks and improve service. And of course, patient monitoring IoT devices (part of the IoMT, Internet of Medical Things) are increasingly used for things like remote patient telemetry, wearable vital sign monitors, etc. For the scope of this industrial guide, suffice to say that healthcare IoT ensures the infrastructure of care (the facilities and equipment) is reliable, efficient, and safe. From keeping backup power systems in ready state, to making sure the air in isolation rooms is properly filtered, IIoT gives healthcare facility managers powerful tools to maintain critical operations uninterrupted. In critical facilities beyond healthcare – e.g. data centers, telecom hubs, military bases – similar IoT implementations protect environmental conditions and power, ensuring high uptime and early warning of any anomalies.

Construction & Engineering

Construction and engineering projects occur in dynamic, changing environments that have much to gain from IoT oversight. One major application is improving construction equipment management. Large construction firms often have equipment scattered across multiple sites, which historically made it hard to track usage and maintenance. IoT solutions now enable companies to track the location and status of all equipment in real time, even across thousands of pieces and sites. A notable French example comes from Bouygues Construction Matériel, which deployed IoT trackers and telematics across more than 20,000 pieces of equipment — from tools and generators to major machinery — spread across its construction sites in France. Connected sensors provide real-time location, utilization, and condition data that feed into a central platform with a one-click digital map of every asset’s whereabouts and activity. By analysing this data, the firm can reallocate idle machinery to where it’s needed most and base maintenance schedules on actual usage rather than guesswork, avoiding both site delays due to missing equipment and unexpected breakdowns from overdue servicing.

Predictive maintenance and safety are tightly interwoven on construction sites, since heavy equipment failure can pose grave dangers. IoT sensors on machines like cranes or excavators monitor critical parameters (engine temperature, hydraulic pressure, vibrations). Advanced analytics then detect early signs of wear or malfunction and predict failures before they happen. Caterpillar, for example, has embedded sensors in its construction machinery and uses a cloud platform to analyze the data. This predictive maintenance approach cut unplanned downtime for customers and also extended the lifespan of equipment by catching issues early. Avoiding sudden equipment failure isn’t just about saving money – it directly improves safety by preventing accidents that might occur from a crane collapse or brake failure. IoT also helps discourage dangerous quick-fix habits (like jury-rigging a broken part to keep working) because issues are addressed proactively, reducing the need for risky improvisation.

Worker safety is further enhanced by IoT wearables and environmental sensors on construction sites. Wearable IoT devices (helmets, vests) can detect if a worker has fallen, wandered into a restricted zone (using geofencing), or shown signs of fatigue or high heart rate, then alert supervisors. Environmental IoT sensors around the site monitor factors like weather conditions, dust levels, noise, and structural vibrations. For example, if high winds are detected by an on-site IoT weather station, an alert can be sent to pause crane operations until conditions are safe. Structural health sensors might be placed on temporary supports or excavation walls to warn of potential collapse or ground shifts. By integrating these IoT feeds, project managers get a holistic, real-time safety dashboard. They can see, for instance, that dust levels are exceeding a threshold in one area and dispatch misting systems or extra PPE to workers, or detect that several workers are in an unauthorized zone near a crane and intervene immediately. The future of construction points to fully interconnected “digital job sites” where everything from worker entry to tool usage to environmental risks is monitored and analyzed for maximum safety and efficiency. Companies adopting these IoT and data analytics measures are setting new safety records and even enjoying lower insurance premiums thanks to documented risk reductions.

Mobile Assets & Fleet Operations

Organizations that operate vehicle fleets – be it trucking companies, service vans, public transit, or heavy vehicle fleets in industries like mining – are leveraging IoT-based fleet management to improve safety, efficiency, and maintenance. Modern fleet telematics systems use IoT devices installed in vehicles to stream data on GPS location, speed, fuel consumption, engine diagnostics, driver behavior and more, back to a central platform in real time. This wealth of data enables a number of optimizations. For one, route optimization becomes largely automated: GPS and traffic data allows IoT platforms to suggest the most efficient routes, avoiding congestion and reducing idle time. Across a fleet, this can significantly cut fuel costs and improve on-time performance. Telematics data also helps with vehicle maintenance. Sensors in the engine and on vehicle components (tires, brakes, etc.) can detect wear or issues and notify managers before a breakdown occurs. For example, if an IoT sensor reports that a truck’s tire pressure is low or engine coolant temperature is high, the fleet manager and driver get an alert to address it immediately, preventing a potential accident or costly roadside failure. Many fleets now perform maintenance on a predictive schedule thanks to these insights, only servicing vehicles when data indicates a need, rather than rigid mileage schedules.

Safety is a paramount concern for fleet operations, and IoT has made big strides here as well. Driver behavior monitoring through IoT devices can track harsh braking, rapid acceleration, speeding, and other patterns. By providing feedback or training to drivers based on this data, companies have reduced incidents and improved driver performance. Some advanced systems include AI dashcams – cameras in the vehicle that use computer vision (an IoT edge device) to detect dangers like a driver distraction or an impending collision, and then warn the driver in real time. For instance, the fleet IoT platform Samsara offers AI dashcams that automatically capture incidents (hard brakes, collisions) on video and upload them for safety reviews. Fleet managers thus gain greater visibility into on-road events and can coach drivers, exonerate them in case of false claims, or identify issues like fatigued driving early. Overall, companies adopting IoT-based fleet management report fewer accidents, lower insurance costs, and improved regulatory compliance (since electronic logging devices, ELDs, can digitally track hours of service for drivers).

Another benefit of IoT in mobile asset management is asset utilization and theft prevention. GPS trackers on equipment or vehicles let you know if something is being underused or if it deviates from its intended area. In industries like logistics, having telematics on trailers or containers means knowing exactly where assets are and that they are secure. Mining and construction companies use similar IoT trackers on their moving assets (trucks, excavators) not just for location but also to monitor loads, cycle times, and idle times. In fact, studies find the average heavy machine wastes a substantial amount of fuel annually just idling – IoT systems can spotlight such idle time and help managers enforce policies to cut it down. All told, IoT-powered fleet and mobile asset management brings a degree of control and insight that was unimaginable in the past: every vehicle “talks” to the operator, providing a steady stream of data that can be turned into safer and more economical operations. As IoT connectivity (including new technologies like 5G and satellite IoT) becomes ubiquitous, even remote or off-road fleets can stay connected, making this approach standard for fleets large and small. Experts predict IoT will play an even bigger role in fleet management in coming years – those who leverage it effectively will have a competitive edge in operational efficiency.

Specialized Infrastructure and Other Sectors

Industrial IoT’s reach extends to many specialized domains that don’t always make headlines but are critical to modern life. Mining is one such sector being reshaped by IoT. In large mining operations, IoT systems monitor both equipment and the environment to improve safety and productivity. For example, autonomous haulage trucks and drill rigs are now deployed in big mines; these heavy vehicles are equipped with IoT sensors and AI to operate without drivers, greatly reducing the risk of accidents from human error. Real-time data links these machines to control centers where operators can supervise multiple vehicles remotely (one person can oversee up to 8 autonomous trucks at once, a number expected to rise). These self-driving systems, guided by IoT, not only prevent accidents but also run efficiently 24/7, maximizing output. In underground mining, IoT sensor networks form a mesh network to continuously monitor conditions like air quality, gas levels, ground stability, and equipment status. Early warnings from these sensors have been instrumental in improving mine safety – for instance, detecting a buildup of methane or early signs of a tunnel collapse so that miners can evacuate and address issues proactively. Wearable IoT tags on miners also help in tracking personnel during routine operations and emergencies. Combined with drones and robotics (which are also IoT devices in this context), mines are able to remove workers from the most dangerous tasks and gather data from deep or inaccessible areas safely. The net effect is a safer, more automated mining operation where decisions are guided by real-time insight rather than on-the-ground guesswork.

Other specialized infrastructure benefiting from IoT includes transportation systems (IoT sensors embedded in roads, bridges, and railways for structural health monitoring and traffic management), water and wastewater utilities (smart pressure and flow sensors throughout water networks to detect leaks or optimize pumping), and agriculture (where IoT-driven precision farming optimizes crop yields and resource use). Even municipal infrastructure like street lighting and waste management is improved via IoT (e.g., smart streetlights that adjust brightness and report maintenance needs, or smart trash bins that signal when they need collection). Essentially, any field operations that involve physical assets can leverage IoT to become more intelligent and responsive. For example, in smart cities, a web of IoT devices – from air quality monitors to parking sensors – feed data to city managers to enhance livability and sustainability. And in oil & gas (which overlaps energy), we see specialized IoT like pipeline monitoring systems that can detect pressure drops indicating a leak and automatically shut valves to prevent spillage.

What ties all these diverse use cases together is the core IIoT principle: gaining data visibility into physical operations, often in real time, and using that information to drive better decisions or automate actions. Whether it’s a mining haul truck, a railway bridge, or an irrigation pump, IoT brings a new level of awareness and control. Notably, these specialized applications often have to deal with harsh conditions (extreme temperatures, remote locales, limited connectivity), so IoT solutions are built rugged – using technologies like low-power wide-area networks (LPWANs), edge computing, and satellite links to ensure reliability. The investment is worthwhile: industries that have been traditionally slow or manual can achieve breakthroughs in efficiency and safety. A Deloitte study on mining notes that IoT and automation together have greatly reduced the risks associated with mobile equipment and hazardous tasks, leading to smarter, safer mining operations. Similar stories are playing out in other specialized sectors, underlining that IIoT’s transformative impact is truly widespread across the industrial world.

Implementation Challenges and Best Practices

While the benefits of industrial IoT are compelling, achieving them requires navigating several challenges. Deploying IoT at scale in an industrial setting is inherently complex – it’s not just a plug-and-play IT project. OT teams must deal with integration into legacy systems, ensure reliability in harsh environments, and manage organizational change as processes become data-driven. Here we discuss some common challenges and expert-recommended best practices for IIoT implementation.

Integration with Legacy Systems and Data Silos

Many industrial organizations have a mix of old and new equipment – from decades-old SCADA systems and PLCs to modern sensors – all speaking different languages. One of the hardest parts of IIoT projects is connecting these heterogeneous devices and aggregating their data into a unified system. In fact, interoperability (or system compatibility) is cited as the biggest challenge by a majority of IIoT adopters. Machines from different vendors often don’t talk natively, so integration requires adapters, gateways, or middleware that can translate protocols and consolidate data. A best practice is to leverage industry standards (for example, OPC UA for industrial device communication, or MQTT for IoT messaging) to avoid getting locked into proprietary ecosystems. Modern IIoT platforms emphasize open APIs and protocol support so they can interface with existing manufacturing execution systems (MES), enterprise resource planning (ERP), or building management systems (BMS) rather than trying to rip-and-replace them. When planning an IoT architecture, it’s crucial to design a data pipeline that can ingest diverse sources and formats, then normalize and contextualize that data (often by building a digital twin model of assets). This ensures all your IoT data ends up in a single pane of glass that operators and analysts can use, instead of creating new silos. It’s also wise to start with a pilot integrating just a few key systems, learn from it, and then expand, rather than attempting a “big bang” integration of everything at once.

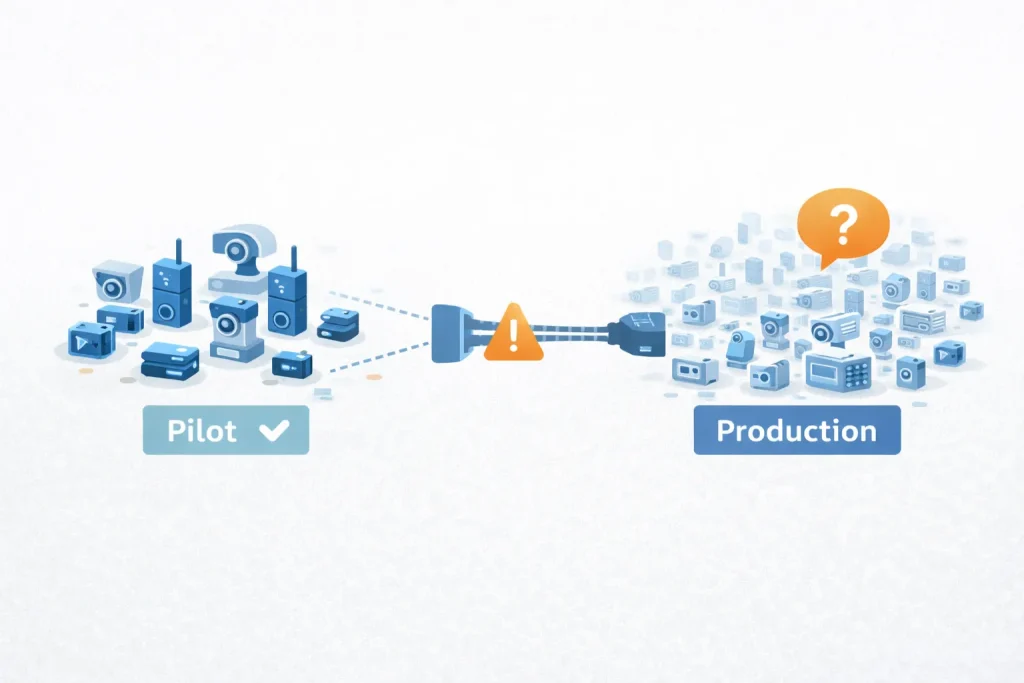

Scalability and Managing Pilots vs. Production

Another challenge is going from a successful pilot to a large-scale, production-grade IoT deployment. It’s common for companies to try a small IoT proof-of-concept – say, instrumenting 10 machines – and see good results, but then struggle to scale it to 1000 machines enterprise-wide. The jump introduces issues of network capacity, data storage, and system management complexity that weren’t apparent at small scale. Planning for scalability from the outset is key. This means choosing IoT solutions (platform software, connectivity, device hardware) that are proven to handle growth in device count and data volume. Cloud-based IoT services can help with elastic scaling, but some industries require on-premises solutions for latency or compliance reasons, so those need careful sizing. Edge computing is a useful pattern: by processing data nearer to where it’s generated (e.g. an edge gateway on site that filters or aggregates sensor data), companies can reduce bandwidth needs and improve reliability even as they scale to thousands of devices. It’s also important to institutionalize the pilot – i.e. move from an ad-hoc project to a formal operational system. One expert recommendation is to treat the IoT deployment “as a system, not a collection of point tools”. In practice, this could mean adopting a managed IoT platform that combines devices, connectivity, data processing, and user applications in one coherent system, rather than trying to DIY assemble many separate components. This approach reduces integration risks and accelerates the path from pilot to real operational value. In short, design your IoT architecture with future expansion in mind, and consider partnering with vendors or platforms that offer end-to-end solutions to avoid getting stuck in pilot mode.

Security and Reliability Concerns

Because IIoT bridges the digital and physical worlds, cybersecurity and system reliability are absolutely paramount. A breach or failure in an IoT system isn’t just an IT issue – it could mean a plant stops running or a public utility is disrupted. Organizations often cite security and data privacy as top concerns holding back IoT adoption. Each new IoT device is a potential attack vector if not properly secured. Best practices here include strong authentication for devices (every device needs a secure identity so that only authorized devices send data), end-to-end encryption of data in transit and at rest, and network segmentation to isolate IoT networks from critical control networks. Regular software updates and patches are also crucial, as IoT devices with outdated firmware can be targets for malware. Additionally, organizations must plan for resilience: power backup for sensors/gateways, redundant communication paths (e.g. cellular backup if Ethernet fails), and robust edge processing so that critical functions can continue even if cloud connectivity is lost. Many industrial IoT systems are being designed to meet strict standards (like IEC 62443 for OT security or new EU cybersecurity frameworks) to ensure they don’t introduce vulnerabilities. For OT teams, it’s important to work closely with IT security experts to integrate IoT deployments into the broader cybersecurity strategy of the company. Conduct risk assessments specifically for IoT scenarios (what if a sensor is spoofed? what if a hacker tries to send false readings?) and have mitigation plans. When done right, a secure and well-monitored IoT network can actually enhance security – for example, by providing more monitoring points to detect anomalies or intrusions in an industrial facility’s operations.

Organizational Alignment (Bridging OT and IT)

As mentioned earlier, successful IIoT projects demand collaboration between those who understand the operations (OT, engineering, maintenance teams) and those who manage information systems (IT, data, networking teams). Historically, these groups have operated in separate spheres with different priorities – OT values safety and reliability above all, while IT focuses on data, integration, and cybersecurity. For IIoT, these worlds collide. A frequent barrier is the cultural and communication gap between OT and IT teams. For example, deploying IoT might require installing software agents on industrial machines, which OT might resist for fear of instability, while IT might insist on certain security controls that OT finds impractical for 24/7 operations. To overcome this, many companies are creating cross-functional teams or roles such as “industrial digitalization manager” that have feet in both camps. It’s critical to get buy-in from all stakeholders early on – involve plant managers, maintenance leads, control system engineers, alongside IT architects and data scientists, in the planning phase. This ensures the IoT solution meets operational needs (e.g. not flooding the control network with data, not introducing unsafe behavior) and also meets corporate IT standards. Clear governance is needed on who owns the IoT data and systems: often OT will own the day-to-day system once it’s running, but IT will provide infrastructure support. Training is another aspect – OT staff may need training on data analytics tools, while IT staff need exposure to operational scenarios and constraints. Analysts from betanews note that bridging IT/OT is “emerging as a new specialization” and is essential for IIoT success. Companies that foster a collaborative culture here – sometimes by colocating teams or running joint innovation workshops – tend to execute IoT projects more smoothly than those where IT and OT remain siloed.

Defining Clear Use Cases and ROI Up Front

Finally, one of the softer but crucial challenges is ensuring the IoT project is driven by clear business objectives and not by technology for its own sake. With all the hype around IoT, some organizations dove in without a concrete value proposition, leading to disappointing results or difficulty justifying further investment. Best practice is to start with specific pain points or opportunities – for example, “reduce unplanned downtime on critical assets by 30%” or “cut energy use in our facilities by $1M/year” or “improve on-time delivery to 98% by tracking shipments.” These goals then guide which IoT data to collect and what analytics to apply. Having well-defined KPIs also helps in measuring ROI post-deployment. As IoT Analytics research found, IoT projects today are more successful when tied to well-scoped use cases and measured outcomes. Additionally, identify quick wins to demonstrate value early (even if small scale) – this builds momentum and executive support to scale further. It’s recommended to involve finance teams in the planning to accurately model the costs (devices, connectivity, integration effort, etc.) versus the expected savings or revenue impact. When stakeholders see that, for instance, a predictive maintenance IoT system can prevent $500k/year in downtime losses and costs $200k/year to run, the business case becomes clear. In 2024, over half of companies planned to increase IoT spending, but they do so cautiously, expecting efficiency from each dollar. Therefore, focusing on high-impact, achievable use cases is the way to secure ongoing investment and scale IoT projects across the enterprise.

In summary, implementing industrial IoT is a multidimensional effort. Companies must integrate new tech with old, ensure security and reliability, manage organizational change, and keep projects aligned with business value. The good news is that success rates are improving – more IoT pilots are translating into full deployments with positive ROI. By learning from early adopters and following best practices like those above, OT teams can avoid common pitfalls. The journey may involve hurdles, but the end result – a resilient, data-empowered operation – is well worth it. As one source noted, IoT complexity appears to be decreasing over time as tools mature, which is fueling strong growth in use case adoption. In other words, deploying IIoT is getting easier and more routine, especially when organizations leverage the right expertise and platforms.

Conclusion

Industrial IoT has moved from buzzword to backbone – it is now a core enabler of efficient, competitive, and safe operations across industries. From smart factories and warehouses to energy grids and hospitals, IoT technologies provide OT teams with x-ray vision into their physical processes and the analytical power to optimize them continuously. In this expert guide, we discussed how IIoT is delivering value in many sectors, the benefits it unlocks (higher efficiency, lower costs, better safety and quality), and the hurdles that must be overcome to achieve those outcomes. A key theme is that while IoT hardware and software are important, the people and process aspects – aligning IT and OT, fostering a data-driven culture, and planning for scale and security – are equally critical to success.

It’s also evident that industrial IoT is not a one-size-fits-all proposition. Each organization has a unique mix of assets, legacy systems, and business priorities. This is why flexibility and a system-level approach matter. Instead of piecemeal gadget deployments, leading organizations are implementing IoT as an integrated system tailored to their needs – often partnering with providers that offer managed, production-grade IoT solutions. These systems are designed to adapt to how the organization operates (supporting multi-site, multi-team structures) and scale as use cases grow. The goal is to turn the raw potential of IoT into a sustainable operational asset, rather than a science experiment. Indeed, many IoT initiatives start with a specific use case but then expand into a broader enterprise IoT platform that supports many departments and functions. This scalability is what separates industrial IoT winners from those stuck in pilot mode.

For OT teams and CTOs reading this, the takeaway is to be proactive yet pragmatic. Leverage the successes and lessons from peers: Figure out where IoT can make the biggest difference in your operations, start with those high-impact projects, and insist on measurable outcomes. At the same time, plan for the long term by building an architecture (people, process, and technology) that can reliably run IoT systems year after year – because once IoT becomes embedded in your operations, it will be as mission-critical as your production lines or power systems. The industrial landscape is becoming ever more connected and data-centric. By embracing IIoT with an expert eye toward best practices, OT leaders can ensure their organizations ride this wave to greater performance and innovation, rather than getting left behind. As the data shows, those who invest wisely in industrial IoT are reaping significant rewards, and the trend is only accelerating. The era of industrial IoT has arrived – now is the time to harness it across your facilities, fleets, and infrastructure to drive the next leap in operational excellence.

References

- European Commission

“Smart grids and meters” - Shaila Afrin et. all, Computers in Industry (2025)

“Industrial Internet of Things: Implementations, challenges, and …” - IoT Analytics (2024)

“The top 10 IoT use cases” - Deloitte (2024)

“Technological advancements elevating health and safety in mining operations”

“Minding the mine: Autonomous mobile equipment improves safety” - JLL

“JLL smart building solutions help cut energy use and improve tenant experience” - Renewable Energy World (2025)

“France’s ‘AMI 1.5’: The Linky meter sets global standards” - EnergyDigital (2025)

“Top 10: Uses of IoT in Energy” - IoT For All (2024)

“18 Industrial IoT Applications & Their Benefits”

“Revolutionizing the Fleet Management Industry with IoT”

“Using IoT for Construction Equipment Management and Maintenance” - BetaNews (2018)

“The challenges of adopting the Industrial Internet of Things” - Tektelic (2024)

“Real Estate Maintenance with IoT Technology“ - RevGen

“Revolutionizing Construction Safety with IoT” - Singu

“IoT Sensors in Real Estate: Top Benefits and Use Cases for Facilities Management” - Madison Technologies

“6 Challenges for Industrial IoT”

Related Resources

- SmartWhere Industry: SmartWhere Industry platform overview

- Smart Buildings: Energy Efficiency and Comfort through IoT